Dispersing agent is used in paper making process as additive to provide uniform stock by separating fiber or particles and to prevent clumping and setting. It is a polymer compound with high molecular weight. Normally it is white fine granulated powder. Dispersing agent is water soluble and has high viscosity in aqueous solution. It is also known as dispersant agent. Very low dosage (approximately 0.2kg to 5kg/ton) of it works properly for separation. There are different types of dispersant chemicals (such as sodium salt of polyphosphate, polyacrylate or silicate) are available in the market but the anionic polyacrylamide is very popular.

Effects of dispersing agent

The paper dispersant has high dispersion efficiency.

- It improves evenness, softness and viscosity of the pulp.

- It increases the wet and dry strength and stiffness of the paper.

- It makes the final paper product more uniform formation, smooth and flexible without creating any pinholes. It improves the opacity, brightness and printability of paper.

- The Dispersing agent also improves the machine speed and increase production. It reduces energy consumption and save pulp beating time.

- Overall, it has economical benefits.

Usage and preparation

Temperature and stirring time is important for the effectiveness of the dispersant agent. The longer stirring time will damage the action of this agent. Always use freshly prepared aqueous dispersant solution; otherwise it will lose its dispersing effect after one or two days. The small amount of this chemical can works properly. The actual dosing of it can vary depends on the various paper product (printing paper, writing paper, tissue paper, newsprint paper, paper board). It may be 0.2kg to 5kg/ton. Use proper amount of the dispersant agent. If you use less amount then it will not works properly. On the other hand, high dosing will create unnecessary waste.

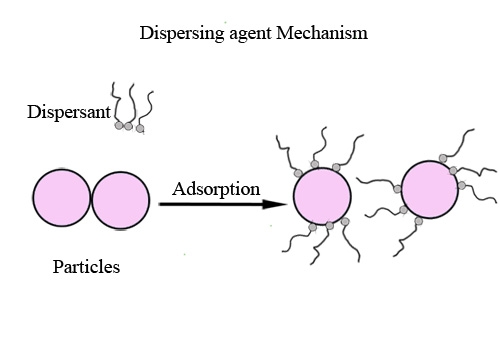

Mechanism of Dispersant agent

The dispersing agent should not a barrier for using other paper making aid or it should not be affected by other agents. It has a surface tension activity. It will wet the solid particles, which is advantageous for the dispersion of the fibers, fillers and other solid particles. The dispersing agent creates a negative attraction between particles thus reduces the interaction among the particles and therefore the fibers, fillers and other solid particles remains separately in the colloidal system which has a better flow properties. Then the uniform stock remains stable for longer time. The dispersant agent is widely used in various paper making process like writing and printing paper tissue paper, newsprint paper, paper boards etc.

Specification:

The specification of Dispersing agent for paper making may be as follow:

- Physical Appearance: Powder.

- PH (1% Dilution): 6- 10.

- Solubility: readily soluble in cold & warm water.

- Effectiveness:- Must be effective for dispersing of the pulp fiber bundles in both acid sizing & alkaline sizing.

- Self life: To be declared by bidder.

- Moisture: ≤1.0%

Dear sir

Please send more details of your product

Temperature and stirring time is important for the effectiveness of the dispersant agent.

Thanks for sharing this information about Dispersing Agent

hello

si .rcan i use it in soap stone in powder it settle ddown in our white water chest.

thankyou

I would like to disperse the fiber for alkali system. What chemicals I can use?