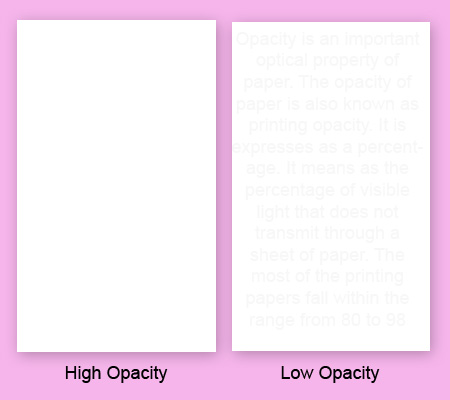

Opacity is an important optical property of paper. The opacity of paper is also known as printing opacity. It is expresses as a percentage. It means as the percentage of visible light that does not transmit through a sheet of paper. The most of the printing papers fall within the range from 80 to 98 percent. The 100% opacity means that 100% of the light cannot transmit through the sheet, and is absorbed in or reflected by the paper’s surface. The lower opacity containing paper have show-through problem; therefore the printing images onto the reverse side or following sheet of a book, magazine or any papers can visible. The tracing paper is the excellent example for low opacity. On the other hand, the higher opacity has less show-through character which allows us to read a page without disturbing by print images on the back side or subsequent sheet.

How can you improve the opacity of paper?

The opacity of paper will be improved when the paper achieved high light-scattering efficiency. It can be done by the amount and kind of filler materials, higher basis weight, unbleached pulp, coating and certain chemicals.

There is a correlation of density with the opacity of the paper. The air spaces in the paper scatter the light. This is why the opaque value of a low density (bulky) paper sheet is much higher than the high density sheet. As a result of refining, the bonding capacity of the fiber increases, so the paper density increases and the opacity is reduced. Although low density paper is less strong than high density paper due to the poor tendency of fiber to fiber bonding.

Wet-pressing and calendering can affect on opacity. Wet-pressing increases the paper density, thus reducing opacity. So to increase opacity, extra wet pressing and calendering should be avoided.

The paper produced from the unbleached pulp has a higher opacity. But this type of paper is less used for printing purposes, because brightness and some other features are more important than opacity for most paper.

The opacity value of paper with higher GSM is higher than that of paper with lower GSM, but in this case the printing costs increase with the purchase of paper.

Another way to increase paper opacity is to add filler material. Again, the opacity values of filler materials of different grades are different; in this case the opacity values of titanium dioxide are higher. On the other hand, the high surface area and irregular shape of the tiny particles of the pulp increase the opacity of paper. Retention aid has a positive effect on opacity due to the filler particles and pulp particle aggregation capabilities.

Determination of printing opacity

The determination of opacity is very importance to both the paper manufacturer and the consumer like printing press. It indicates the ability to hide what is behind it. The paper that has high opaque value will have the better hiding power. The opacity of paper is defined as the ratio of the two reflectance factor of a single sheet with black backing to that with a backing consisting of a pad of the same paper, multiplied by 100. [TAPPI Standard T 519]

Printing opacity=R0/R∞ ×100%

TAPPI opacity=R0/R0.89×100%

Where,

R∞ = Reflectivity of thick pad of paper

R0 = Reflectance of a single sheet of paper backed by a blackbody

R0.89 = Reflectance of a single sheet of paper backed by material with reflectance of 0.89

Excellent write-up on 0pacity .

Nice write up on Opacity, but it doesn’t answer the one question I wanted answered. My question is do you have or know where to get 100% opacity paper? I want it to make game cards for review games for my students to play. At present I am using glue to make a 3 layer laminate of white paper / Aluminum foil / white paper, but over time the layers come apart.