There are different methods are available for pulp washing such as rotary vacuum washer, rotary pressure washer, pressure and atmospheric diffusion washers, horizontal belt washer and dilution/extraction equipment. Among them the rotary vacuum washer method is well-known to paper makers for long times. This method of pulp washing is employing a series of rotary vacuum washers working in a countercurrent flow system. Here, rotary vacuum washer is described.

Used chemical recover is the most important part for Kraft pulping process. The chemicals are separated from fiber as black liquor. Concentration of the black liquor is very significant for recovery; on the other hand pulp should be well washed. In one word, the liquor should be minimum dilution to get better evaporation benefits and better wash pulp.

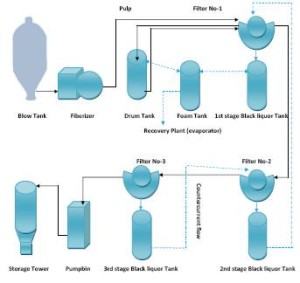

Rotary Vacuum Washer may contain three or four single stages. These arrangements are necessary to achieve an overall satisfactory elimination of 99% of the “washable” liquor solids. Every single stage contains a rotating vacuum drum washer. The drum washer is a cylinder that covered with clothes. The clothes of washer may be made by synthetic fabric or metal wire. Washer drum rotated in a vat, which contains the mixer of pulp and liquor. When the rotating drum washer enters the mixer, then the vacuum is started and a thick layer of pulp developed on the clothes of washer. The pulp layer is disconnect by a plate (known as doctor blade) and ready for next stage. The black liquor is collected in a tank. To keep minimum dilution of the black liquor a typical countercurrent mechanism arranges.

There are many factors that affect brown stock washing displacement efficiency such as fiber characteristics, shower characteristics, sheet formation/thickness, and operating factors. Fiber characteristics involve Pulping process, Species, Stock hardness and freeness; whereas Shower Characteristics engages the method of showering application, nozzles, temperature and shower distribution. If the shower does not place at right position and does not choice right nozzles, then it may creates foam and affects on brown stock washing.

Dilution factor, air in stock, stock temperature, fabric mesh and fabric unclean are most significant operating factors. Normally, a higher dilution improves pulp washing performance. But at this time it dilute the black liquor that effects on evaporation. Hence, it is batter to keep balanced to get washing benefit achieved. In this system a specific amount of air is continuously pulled throughout the pulp sheet, it may create foaming problems and affects on pulp washing. It could be overcome by installing large seal tanks; it helps air to escape and foam bubbles to break. Sheet formation that depends on loading, Vat consistency and rotational speed also affects on pulp washing.

Washing efficiency can be increased with a quality defoamer. The right defoamer can add millions of dollars of value to your pulping operation by increasing pulp production rates, washer efficiency, increased recycled white liquor, less washer screen clogging, reduced energy costs, and cleaner pulp. Let me know if I can get you information about SIXIN’s high quality defoamer, silicone and non-silicone based.

joearnold@sixinchem.com

I think The purpose of bleaching is to remove remaining dark-colored lignin impurities in the pulp and thus meet certain quality criteria but how to remove chemicals ?

do you have method for soda loss

We are looking for 250 BDT/d horizontal belt pulp washer, could you please send us your technical offer ?

We are looking for 250 BDT/d horizontal belt pulp washer, could you please send us your technical and price offer, we send asking for proposal in 2021, please reply

Best regards

Dr. Eng. Mohamed Abdullah